Full control of the supply

100% ownership

Production and stock

Production capacity: 480.000.000

10% of the estimated Darboven’s annual demand in security stock

Risks management – time to market

No shipments to Darboven without visual control of all capsules

Capsules delivered in columns to avoid feeding problems with cylinder machine

Mold: independant cavities for easy maintenance and fast reactivity

Mold: optimum size to avoid rupture d’appro

Suppliers selections

Reliable and well known

Geographically close to our production

Manufactured in France

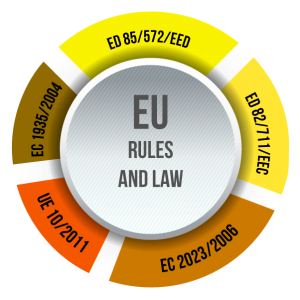

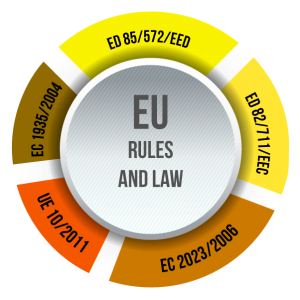

Full respect of EU regulations

GMP and Quality Assurance

Dedicated clean room/ISO/HACPP

Full traceability

Bacteriological control

Recall procedure

Quality Control on each batch

Robot

Visual controls

13 tests on each batch

CoA

Capsule Certifications

BPA/Epoxy/Food contact/Migration

Intellectual Property

Herrburger report / Eu patent

Monitoring EU legislation

PA and recycled polymer

Perfect compatibility

Quality in cup

Compatibility

Capsule volume

Capsule holes

Consultancy services

Coffee roast for capsule

Coffee ground / grinder

Packaging

Filling équipement

Tools adaptability to reduce time to market

Mold size adapted to

Independant 24 cavities

On going research and development

Hermetic capsule

Bio sourced capsule

Bio degradable capsule

Other capsule system